Laser light in the car industry: Questions and answers on innovative laser technology

Great opportunities for smart car lighting

How exactly is the laser beam produced and what are the individual processes?

The basis for the laser full beam is a development from the research laboratories at OSRAM Opto Semiconductors in Regensburg. Blue laser diodes with sufficient power of at least one watt have only been available for a few years. They are based on the indium gallium nitride technology and were originally developed for professional projector technologies. The luminous color on such laser diodes can be enhanced further by adjusting the mixing ratio of the elements indium and gallium.

It is not easy however to transfer laser diodes to vehicles: laser diodes must function in a temperature window of - 40 to +100 °C.

"It was hard work to develop laser diodes that function reliably at temperatures of more than 50°C," reported Hans-Joachim Schwabe, for such temperatures are quickly reached if solar radiation is intense.

When did OSRAM begin with the development of laser light, what were the technological milestones, and who were the project partners?

Automotive Laser Activated Remote Phosphor (LARP) development started approximately four years ago. Milestones were the development of the various concepts, as well as the development of the prototype level through to series production.

Where did this research and development take place?

The development of the automotive LARP systems is a global collaboration between various divisions of OSRAM. The Specialty Lighting, Opto Semiconductors, and Corporate Technology divisions have worked together very closely.

How does the laser for the car headlight differ from lasers for other areas (for example, entertainment)?

The key differences in automotive LARP systems from other areas are the specific customer requirements from the automotive sector regarding design space and environmental conditions, as well as the interfaces to the headlights, time, and cost pressure.

How much does a headlight with laser light cost? How can costs be reduced in future?

LARP systems are still expensive solutions for the premium vehicle manufacturer. The costs can be reduced by increasing volumes. This can be done, for instance, by implementing the LARP systems in mid-level vehicles.

What is the advantage of laser light over other lighting technologies (halogen, xenon, LED)?

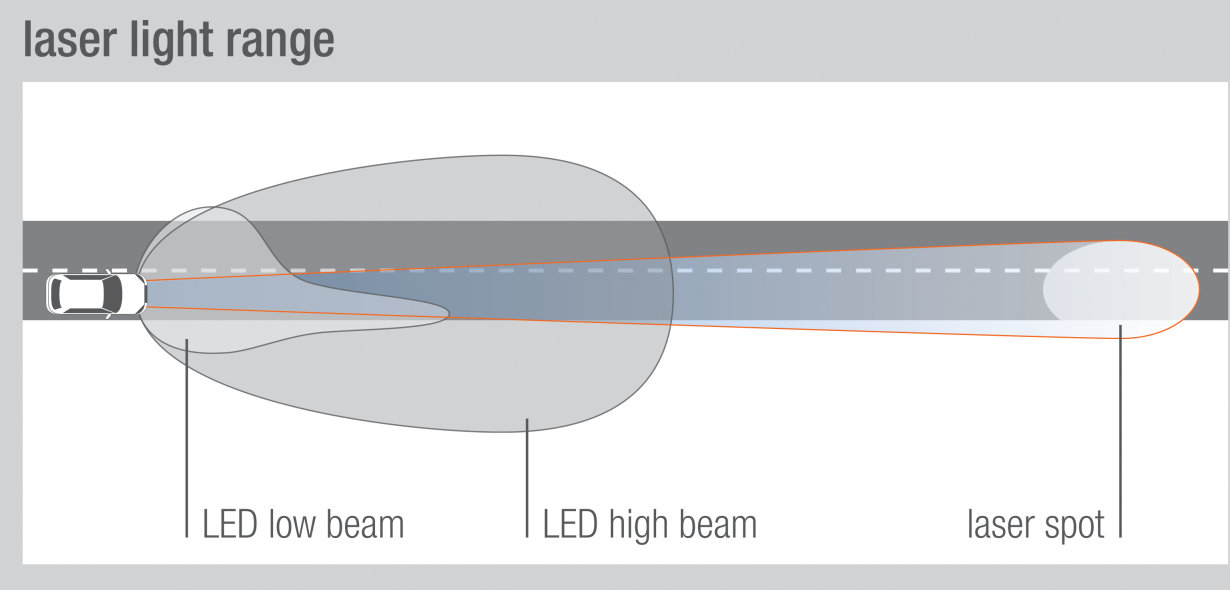

Laser light generates extremely high luminosity, which is far above the brightness of conventional technologies. The brightness is also four times that of the LED. The extreme brightness allows the use of very small optical components. These can be arranged as required in the headlight, thus creating a good deal of design freedom for the headlight designer. Conversely, optical systems of similar size, as used in LED applications, lead to extreme ranges. The current series production vehicles attain ranges of up to 600 meters.

What is the current status, and what does the OSRAM laser light roadmap look like for next year?

LARP is subject to considerable development pressure. Alongside today’s complex systems used in series production, in the future, there will also be smaller packages allowing headlight designers a lot of freedom to open up new fields of application. In the future, complex modules with a corresponding flux performance will be offered, as well as small compact modules with lower performance.